Silicon Metal Powder

Properties

Silicon metal powder is a silver grey or dark grey powder with a metallic luster.The highly versatile material features a high melting point, excellent heat resistance, high resistivity, and antioxidant effects. It is an absolutely vital component in the production of a variety of electronics components as well as an additive in the smelting of many different types of metals and metal products.

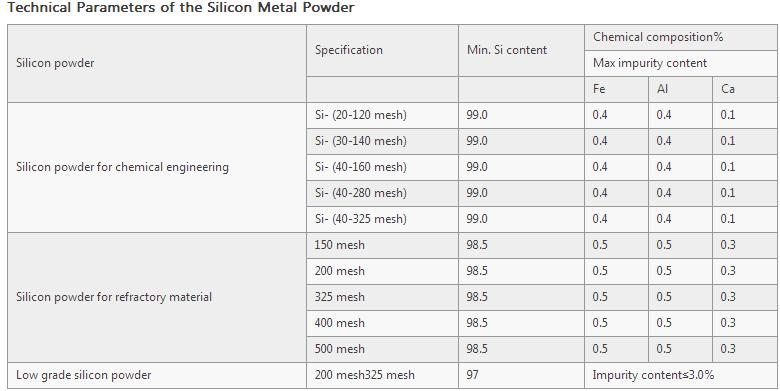

Technical Parameters of the Silicon Metal Powder

Note: We can process the 2202, 3303, 411, 421, 441, 553 and other silicon materials into silicon powder of different granu-larities according to your needs.

Applications of the Silicon Metal Powder

1. Industrial silicon powder is widely used in the production of refractory materials and metallurgical applications due to its high temperature resistance, wear resistance, and oxidation resistance.Some examples of its application are furnace walls, kilns, and kiln furniture.

2. In organic silicon chemical operations, silicon metal powder is a base material used in the synthesis of organic silicon products. The powder is often used to manufacture silicon monomers, silicone oils, and silicone rubber preservatives. As an additive, the powder provides a significant increase in temperature resistance, electrical insulation, corrosion resistance, waterproofness, and many more highly valuable properties.

3. Some of the more valuable applications of silicone powder involve using silicon wafers to produce integrated circuits and other electronics components. The powder undergoes a drawing process, turning it into monocrystalline silicon wafers. High-tech industries are essentially driven by silicon.

4. In the metallurgical casting industry, industrial silicon powder is an additive for nonferrous alloys and alloying agents in silicon steel in order to greatly enhance the hardness of the finished steel products. Silicon powders are also used as a metal reducing agent for modern ceramic alloys, providing additional hardness and heat resistance.